Airless systems

Optimum product protection and hygienic use

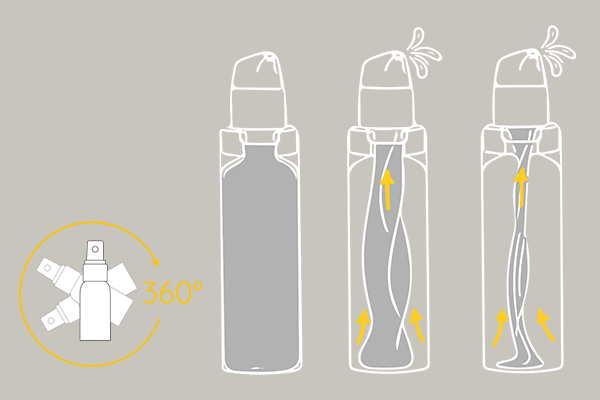

A bag-in-bottle system or airless system is an innovative packaging solution in which the medium is contained in a flexible bag inside a rigid bottle (glass or plastic) or other container (jar). The bag is typically made of a robust, flexible material (such as plastic) and contains the product (e.g. liquid, gel, cream), while the outer bottle forms a protective cover.

It is often referred to as an airless system, as the dispensing process is air-free. This means that the bag is compressed or vacuumised when the pump is activated, whereby no air can penetrate. Ventilation to the outside prevents contamination or drying out of the medium. This packaging solution is therefore particularly suitable for product contents with few preservatives and protects against environmental influences such as oxygen or bacteria. UV light protection is guaranteed both by amber glass (Pharmacos airless system) and by the additional PE bag.

With each use, the bag becomes increasingly empty and the liquid is squeezed out of the bag. This results in simple and optimised residual emptying after the flexible pouch ensures that the entire contents of the product are removed.

The pump mechanism makes the application hygienic and user-friendly. The system can also be used 360 degrees. Overhead use is a decisive, convenient advantage for the end user.

There are basically two different systems:

Bag in Bottle (BiB): The system consists of a bottle, an inner bag and a pump. Here, a bag inside the bottle is pulled together by activating the pump.

Drag piston system: Here, a piston is inside the bottle, which is pulled up when the pump is activated. The drag piston is an additional plastic component.

Airless in-house developments from PACKSYS:

In-house development: Pharmacos Airless

The Pharmacos series made of amber glass creates a standardised, cosmetic design of bottles and jars in different sizes and volumes. The 25 and 45 ml bottle sizes are available as an airless system. As the inner bag is fitted directly into the glass bottle, there is a reduction in plastic components compared to standard airless solutions. The amber glass bottle consists of at least 50% recycled glass. The thread of this in-house development is: 24-410.

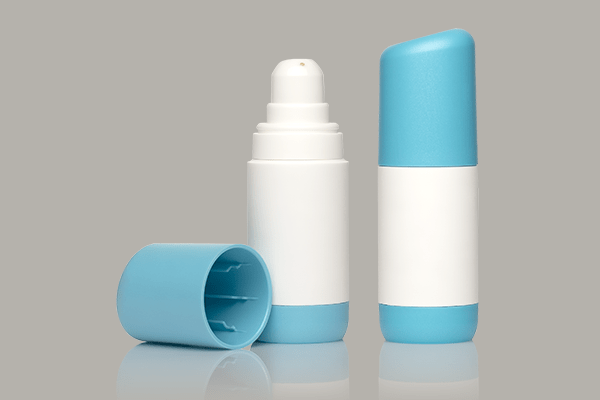

In-house development: Gel dispenser

The gel dispenser is also an in-house development from PACKSYS and is an airless system made of plastic. In addition to the pump, the bag-in-bottle system includes a plastic bottle with a multi-layer inner bag.

Airless standard products from PACKSYS:

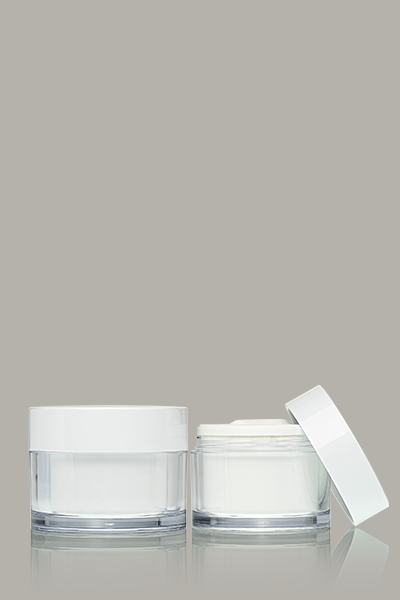

Standard: Airless glass

In the standard product portfolio, PACKSYS offers airless systems in glass. These consist of a pump, a glass jar (frosted) and a plastic bottle with an inner bag. The inner bottle is available in volumes of 15, 30 and 50 ml. The pump fits all sizes. It is possible to refill and reuse the glass jar.

Standard: Airless plastic

PACKSYS also has plastic airless systems in its standard range. The PP bottles are available from 15 to 500 ml. However, they are also available in PCR material. Depending on the application in the pharmaceutical or cosmetics sector, the inner bag can have a 4- or 3-layer structure. The bag-in-bottle systems can be combined with lotion pumps and topical atomisers (standard, oral, nasal). Filling volumes can be from 0.2 ml to 0.8 ml. The base of the bottle is characterised by a straight pinch seam and two ventilation holes.

Standard: Airless jar

If plastic jars are required in combination with an airless version, you can purchase this 50 ml jar.

If you have any questions, please contact:

Franziska Finger

Team Leader Business Development

Or get in touch with your direct contact at PACKSYS.